Homepage ← Control of Storage Insects → Aeration Storage Technology

Aeration Storage Technology

Consumer and regulatory agencies for environmental protection demand for chemical-free and contamination-free products. This is a general tendency that industry finds difficult to conform with because insecticides are often necessary to prevent economic damage.

Aeration systems

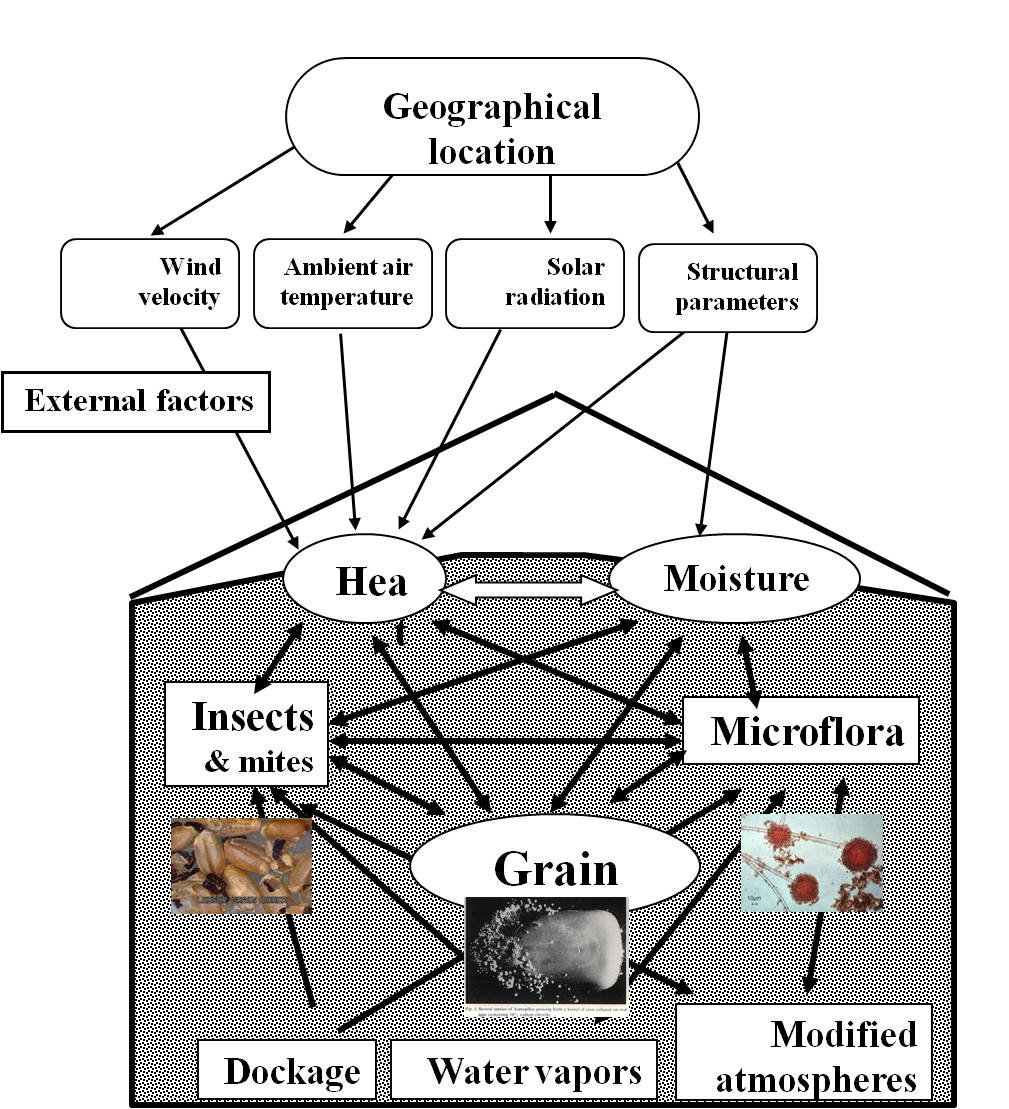

At present, forced aeration of grain is one of the most effective non-chemical methods in use for control of stored grain conditions, biological activity, and grain quality losses. Air temperature and humidity are regulating factors in the survival, development, and reproduction of all living organisms of the storage ecosystem, (including microflora, insects, and mites). Air characteristics suitable for aeration, should be selected that will prevent or suppress the development of damaging organisms. Automatic aeration system controllers are one of the most cost effective tools available to grain managers. The benefits of using computer-based monitoring and control systems that integrate grain temperature monitoring with aeration control that are suitable for major grain terminals and storage facilities needs further exploration. Historical weather data can be used to help predict cooling patterns in different geographical regions can be integrated with insect population models to show how aeration can help limit insect pest populations. These predictive models are useful tools for demonstrating the impact of aeration on insect pest populations in grain and in commercial silos, and how aeration can be integrated with other control options.

Chilling of Grain by Refrigerated Air

Aeration using ambient air may not be sufficient to control fungi on moist grain, protect grain against mites and insects, control self-heating of grain, preserve the germination capacity and quality of stored grain in warm climates, or when warm grain is stored immediately after harvest. In answer to these situations, refrigerated air units for chilling grain have been developed for commodities that can justify the added expense of refrigerated aeration cooling.

Refrigerated aeration has been used for cooling dry grain in subtropical climates when ambient temperatures are too high for successful insect control by aeration with untreated air. Refrigeration involves considerable investment, but together with the dehumidified air method, it could provide answers to the practicability of aeration for safe commercial storage in tropical climates.

Aeration using ambient air may not be sufficient to control fungi on moist grain, protect grain against mites and insects, control self-heating of grain, preserve the germination capacity and quality of stored grain in warm climates, or when warm grain is stored immediately after harvest. In answer to these situations, refrigerated air units for chilling grain have been developed for commodities that can justify the added expense of refrigerated aeration cooling. In this type of aeration process, ambient air is conditioned by passing it through the evaporator coil and a secondary reheat coil of the refrigeration unit, and then blowing the chilled air into the grain bulk via the existing aeration system.

Grain chilling is accepted as a grain conditioning technology in much of Western Europe; currently most new units appear to be marketed in Southeast Asia. In the 1960s grain chillers were primarily used as a means of preserving high moisture (moist, damp) grain. Later, grain chilling was applied to improving storability of sensitive commodities subject to development of heat foci (hot spots), i.e. for soybeans and maize, and preserving the quality of high value dry grain, seeds and edible beans, primarily against mites and insects.